Table Of The Content

- Introduction

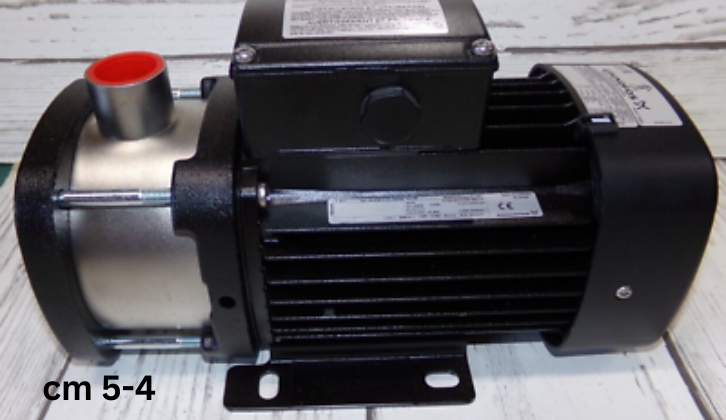

- Definition of CM 5-4s

- Importance of Understanding

- What is?

- Basic Explanation

- Historical Background

- Technical Specifications of

- Key Features

- Performance Metrics

- Applications of

- Industrial Uses

- Commercial Applications

- Advantages of

- Efficiency

- Cost-Effectiveness

- Challenges Associated with

- Common Issues

- Mitigation Strategies

- In Comparison to Other Standards

- vs. CM 4-3

- vs. CM 6-5

- How to Implement in Your Organization

- Step-by-Step Guide

- Best Practices

- Case Studies of Implementation

- Success Stories

- Lessons Learned

- Future Trends and Developments in

- Upcoming Innovations

- Industry Predictions

- Regulatory and Compliance Aspects of

- Relevant Regulations

- Compliance Checklist

- Training and Certification for

- Available Courses

- Certification Process

- FAQs about

- Commonly Asked Questions

- Expert Answers

- Conclusion

- Summary of Key Points

- Final Thoughts

Introduction

In today’s fast paced world, understanding specific standards and protocols is crucial for businesses and individuals alike. One such important standard is CM 5-4. But what exactly is. And why should you care about it? Let’s dive into the nitty-gritty of, exploring its significance, applications, and everything in between.

What is CM 5-4?

Basic Explanation

CM 5-4 is a technical standard widely recognized in various industries for its robustness and reliability. It sets forth specific guidelines and criteria to ensure consistent performance and quality.

Historical Background

The development of CM 5-4s dates back to the early 2000s when there was a growing need for standardized protocols to enhance efficiency and interoperability across different systems. Since then, has evolved, incorporating advancements in technology and industry feedback to remain relevant and effective.

Technical Specifications of CM 5-4

Key Features

CM 5-4s boasts a range of features designed to optimize performance:

- High Durability: Ensures long-lasting performance under various conditions.

- Scalability: Easily adapts to different operational scales.

- Interoperability: Seamlessly integrates with other systems and standards.

Performance Metrics

The performance of CM 5-4s is often measured through metrics such as throughput, reliability, and efficiency. These metrics help in assessing its suitability for specific applications and ensuring it meets the required standards.

Applications of CM 5-4

Industrial Uses

In industrial settings, CM 5-4s is utilized for:

- Manufacturing Processes: Ensuring consistent quality and efficiency.

- Automation Systems: Enhancing precision and reducing errors.

Commercial Applications

Commercially, CM 5-4s finds its place in:

- Supply Chain Management: Streamlining operations and improving tracking.

- Product Development: Facilitating innovation and faster time-to-market.

Advantages of CM 5-4

Efficiency

One of the standout benefits of CM 5-4s is its efficiency. By adhering to this standard, organizations can significantly reduce waste and optimize resource use.

Cost-Effectiveness

Implementing CM 5-4s can also be cost-effective. It minimizes the need for rework and repairs, leading to substantial savings over time.

Challenges Associated with CM 5-4

Common Issues

Despite its advantages, CM 5-4s is not without challenges. Some common issues include:

- Implementation Complexity: The initial setup can be complex and time-consuming.

- Maintenance Requirements: Ongoing maintenance is necessary to ensure continued compliance.

Mitigation Strategies

To overcome these challenges, organizations should:

- Invest in Training: Ensure that staff are well-versed in CM 5-4s requirements.

- Regular Audits: Conduct frequent audits to identify and rectify issues early.

CM 5-4 in Comparison to Other Standards

CM 5-4 vs. CM 4-3

While CM 4-3 laid the groundwork, CM 5-4s offers enhanced features and improved performance metrics. It provides better scalability and interoperability.

CM 5-4 vs. CM 6-5

CM 6-5, on the other hand, is a more recent standard that builds on strengths. However, Remains widely used due to its proven track record and reliability.

How to Implement CM 5-4 in Your Organization

Step-by-Step Guide

- Assess Your Needs: Determine if aligns with your operational requirements.

- Plan the Implementation: Develop a detailed implementation plan.

- Train Your Team: Provide comprehensive training to ensure everyone is on the same page.

- Deploy the Standard: Begin the implementation process, starting with pilot projects.

- Monitor and Adjust: Continuously monitor performance and make necessary adjustments.

Best Practices

- Engage Stakeholders: Involve all relevant parties from the beginning.

- Document Everything: Keep detailed records of the implementation process.

- Be Flexible: Be prepared to adapt your approach based on feedback and results.

Case Studies of CM 5-4 Implementation

Success Stories

Many organizations have successfully implemented. Leading to significant improvements in efficiency and cost savings. For example, a leading manufacturing firm saw a 20% increase in productivity within the first year of implementation.

Lessons Learned

From these implementations, several lessons have emerged:

- Preparation is Key: Thorough preparation can prevent many common issues.

- Continuous Improvement: Regular updates and improvements are essential for sustained success.

Future Trends and Developments in CM 5-4

Upcoming Innovations

The future of looks promising with innovations such as:

- AI Integration: Leveraging artificial intelligence to enhance performance and predictive maintenance.

- IoT Compatibility: Incorporating Internet of Things (IoT) capabilities for real-time monitoring and control.

Industry Predictions

Experts predict that will continue to evolve, with increasing adoption across various sectors and further refinements to meet emerging needs.

Regulatory and Compliance Aspects of CM 5-4

Relevant Regulations

Adhering to often requires compliance with various regulations. These may include industry-specific standards and government regulations.

Compliance Checklist

To ensure compliance:

- Review Regulations: Regularly review relevant regulations and update your practices accordingly.

- Conduct Audits: Perform regular compliance audits to identify and address any gaps.

Training and Certification for CM 5-4

Available Courses

Several training courses are available to help professionals gain expertise in. These range from introductory courses to advanced certifications.

Certification Process

The certification process typically involves:

- Coursework: Completing the required coursework.

- Examination: Passing a certification exam.

- Ongoing Education: Engaging in continuous learning to maintain certification.

Conclusion

In conclusion. Is a vital standard that offers numerous benefits for various industries. Its efficiency, cost-effectiveness. And adaptability make it a valuable tool for businesses looking to improve their operations. By understanding and implementing, organizations can stay ahead of the curve, ensuring consistent quality and performance.

FAQs about CM 5-4

Commonly Asked Questions

- What is the main benefit of?

- The main benefit is its ability to enhance efficiency and reduce costs.

- How long does it take to implement?

- Implementation time can vary but generally takes several months.

- Is suitable for small businesses?

- Yes, can be scaled to fit businesses of all sizes.

- What industries use the most?

- Industries like manufacturing, logistics, and product development commonly use.

- Can be integrated with other standards?

- Yes, is designed to be interoperable with other standards.